Products

Electrodes

Thanks to their outstanding properties, diamond electrodes have displayed steady market growth in recent years. They can do amazing things in particular in water treatment and electrochemical synthesis.

They have a particularly wide electrochemical window, which makes it possible, for example, to produce extremely strong oxidising agents such as OH-radicals directly from water without adding any further chemicals.

Many years of development, extensive field tests and use on an industrial scale over a long period of time in aggressive media affirm that DiaCCon diamond electrodes offer excellent long-term stability.

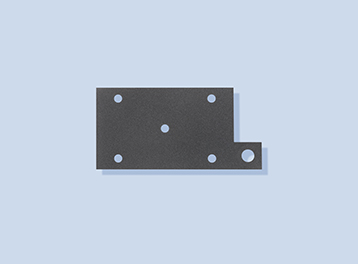

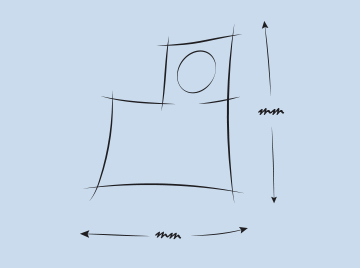

Standard electrode

Bärbel type

Dimensions

(excluding terminal lug):

250 mm x 150 mm

Active electrode surface area:

750 cm2

Layer thickness:

≥ 12 µm

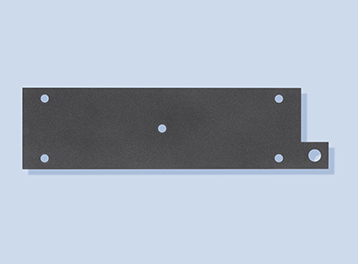

Standard electrode

Barbara type

Dimensions

(excluding terminal lug):

500 mm x 150 mm

Active electrode surface area:

1500 cm2

Layer thickness:

≥ 12 µm

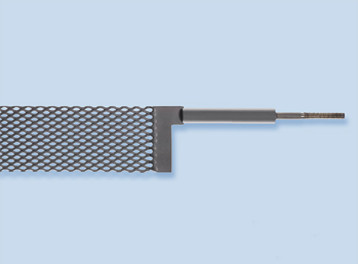

Expanded metal electrodes

Expanded metal grates in a wide range of different designs with and without contacting elements welded on.

Special geometries

Geometries produced specifically to meet customer requirements.

Economical production thanks to waterjet cutting.

Welded electrodes

Particularly large-scale electrodes or complicated geometries can be produced by welding.

Substrates used:

Niobium (standard material), silicon, tantalum, graphite, ceramics

Coatable geometries:

Boards, expanded metal grates, rods, 3D geometries

Coatable dimensions:

| Standard types: | 500mm x 150mm (Plate electrode) |

| 250mm x 150mm (Plate electrode) |

Small sizes in small quantities can be fabricated economically through the use of waterjet cutting. Larger dimensions are possible on request. Very large-scale types or types with complicated shapes can also be welded.

Diamond layer types:

Electrically conductive diamond (boron-doped) Minimum layer thickness 12 µm (standard), up to 100 µm possible